Design

My Design 1 professor, Steve Collins, preached a simple yet powerful principle for design: "Iterate. Iterate. Iterate." It's a mentality that drives a bias towards action for rapid completion of calculated design steps, learning from what goes wrong, then spinning the design loop again. From a macro view, it's a methodical approach, yet from the micro view, the iterative approach drives a sense of urgency, the need to innovate and derive creative solutions, and the important skill of being resilient to setbacks. This iterative mindset has helped me to push like hell through designs that at certain points seemed to be crumbling and output some pretty cool results.

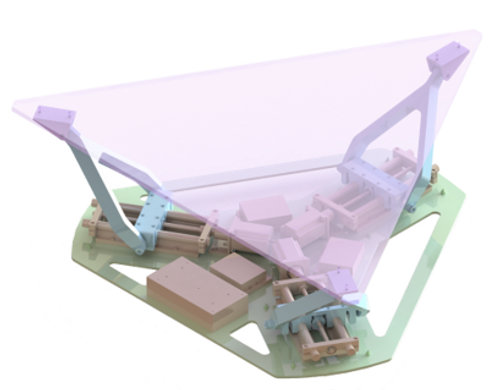

Trulie Golf Platform

Course: Design 2

- The design space was wide open, simply build something that we believe there's a market for within a semester and a budget of $2,000.

- I owned CAD for the top plate and clevis assembly design, manufacture of clevises, establishing component sizing requirements such as motor torques and clevis joints via analyzing forces through the system, FMEA, cost report, and life cycle analysis.

- The team and I took the design from white paper to a functioning prototype that we were able to get user testing on within the course of four months, lessons learned from build and test are included in the final report.

Featherweight Ankle Exo-Skeleton

Course: Biomechatronic Systems for Humans

- Brought a conceptual design to a functioning prototype for an assistive walking exoskeleton with an electroadhesive clutch

- I owned the CAD design and machining of the "forkplates", steel inserts which were necessary to prevent abrasion of carbon fiber from removable bolted joints, installed/calibrated/tested strain gauges with an amplifier to read ankle torque values, and supported integration and testing of the system as a whole

- Lesson learned: small leadless strain gauges should be avoided, either find a location with more surface area to attach the strain gauges or find a strain gauge with leads small enough to fit the purpose.

Torque Rod Design

Course: Advanced Design (Design 3)

- Provided with two mounting plates, a gap, and the requirement to support a mass hanging off a rod from one of the mounting plates and maintaining a deflection of <10deg. The objective was to optimize for mass

- I owned the epoxy analysis, component stress analysis, component FEA, rod selection, endpiece design and machining, and surface prep

- My two-person team achieved that years lightest design that succeeded in maintaining the 10deg deflection requirement

- Lesson learned: Epoxy usage (DP420 in this case) often require a detailed surface prep procedure which is contingent on the materials and epoxy in use, but when applied appropriately can provide a quality attachment when bolted connections aren't ideal due to geometry or the potential structural damage a through-hole could cause.

Adjustable Luggage Bag

Course: Advanced Design (Design 3)

- Identified a market opportunity and created a design and initial prototype within a month

- I owned the conceptual design, component CAD design, and cost analysis

- Lesson learned: design adjustability makes the interplay between constraints and tolerancing an essential item to test and balance appropriately for proper functionality. We wanted the flexibility to adjust the handle to multiple positions easily, but this resulted in excessive slop in each individual position, and local deflections that we didn't account for due to assumed rigidity caused an under-constrained system when moving from one handle position to the other. Future design iterations would have seen a tightly toleranced locating feature to align both handle supports, tightly toleranced positioning holes, and the hinges pin passing fully through the base of the handle as opposed to being one sided.

Thor's Hammer Gripper

Course: Design 1

- Designed a mechanism that could actuate to grip a complex geometry ("Thor's hammer") and hold the item as the arm the mechanism is attached to swings freely from a 90-degree starting point

- I owned the conceptual design, initial CAD concepts, calculating forces within the system to drive component sizing, catalog component selections, and determining the attachment schemes.

- Lesson learned: fishing line seemed like a good idea for minimizing the mass and complexity of the system while transferring the torque from the motor to key structural areas of the design (instead of using gears or significantly beefing up long cantilevered beams) due to its small diameter and high strength, but intelligent cable management is critical. We succeeded on test day but trying to repeat results after showed the line getting tangled and not providing enough torque through the system to clasp the hammer.

Analysis

Soup Cooling via Gas Injection

Course: Thermal Fluids Design

- The problem statement was to design a cost and space effective way to quickly cool commercial levels of soup (~20 liters) so that bacteria build-up didn't occur and soup consistency was maintained

- I owned initial conceptual designs of a direct gas injection system solution (we also traded a surface cooling option and a heat transfer fluid option but ultimately selected direct gas injection).

- I coordinated the thermal analysis of the system, determined the requirements of liquid nitrogen needed, developed the concept and equations for analyzing the nitrogen bubbles as they ascend through the soup, and derived the equations for the pressure and temperature control system for the liquid nitrogen/nitrogen entering the system.

Multi-Criteria Decision Analysis for EV Cathode Material Mining Opportunities

Course: Electrochemical Energy Storage Systems

An interesting look at the EV market material dependencies and where key players might find it advantageous to invest.

Side note: Looking back this was a somewhat prescient advocacy report given Tesla's recent investment in 10,000 acres of lithium-rich clay deposits in Nevada.

Better Energy Living Initiative

Course: Energy Systems

Open project to outline a new energy startup, define the competitors, define the early adopters, how the business will grow, and why the business would be valuable.

Fun Fact: A successful project from this course the year prior was put together by Thomas Healy (also a football teammate of mine at CMU) for his concept for regenerative breaking for semitrucks, this idea became a startup, Hyliion, and that startup just went public making Thomas an on-paper billionaire... This project, unfortunately, did not have the same fate, but it was still a fun exercise :)